Robotics applications Lab Products

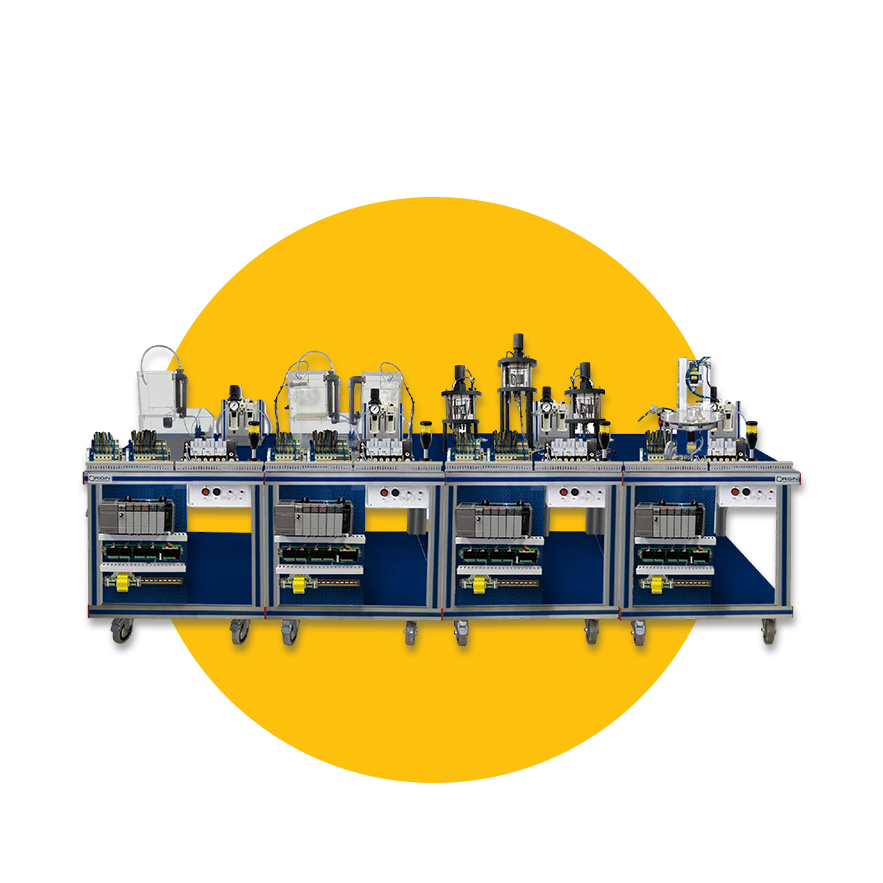

Automated production line with robot training unit

Code : (MTR-41)

The main goal of the (MTR-41) system is to treat the input water to produce the intended bottled product.

The process of the (MTR-32) is as follows:

Initially, the input water undergoes filtration and is then transferred to the mixing station.

Subsequently, the mixed water is directed to the industrial control processes workstation, where three distinct industrial controllers oversee the temperature, level, flow, and pressure of the product.

Finally, the subsequent workstation bottles the product.

The design of the (MTR-32) system by EDIBON enables users to grasp fundamental automation concepts such as operating an Ethernet network or programming a PLC, as well as other areas like pneumatic and electro-pneumatic systems.

• Flexible Manufacturing System (FMS) overview.

• Pneumatics and electro-pneumatics introduction.

• Vacuum technology overview.

• Sensor detection study.

• Testing automatic system digital inputs and outputs using a PLC.

• Adjusting manufacturing parameters using a PLC.

• Pneumatic application setup.

• Human-machine interface systems (HMI) introduction.

• Study of automatic control in an industrial system.

• Flexible manufacturing system control through a central PLC in an Ethernet network with local PLC at each workstation.

• Managing the flexible manufacturing system using the HMI device.

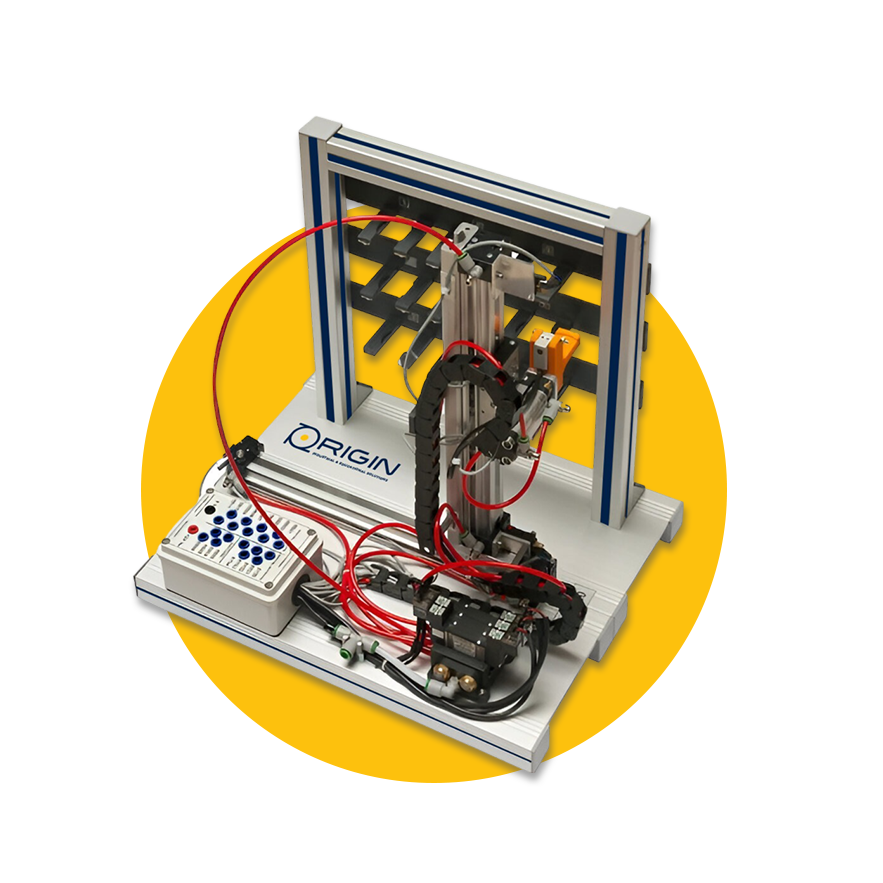

Cartesian control storage

Code : (MTR-42)

The pieces in the (MTR-42) unit are stored based on their material type. A 3-axis Cartesian system is used to move the pieces to and from three different levels.

There are 9 positions in the store, with 3 positions on each level.

A sensor on the gripper is used to initially check the store to determine which positions are available and which are already filled.

Translations along the X and Y axes are performed by two pneumatic cylinders, while a microcylinder connected to the gripping system handles the movement along the Z axis.

The module is constructed on a segmented aluminum base, making it easy to relocate within the laboratory.

• Introduction to Electro-pneumatics.

• Methods for distributing components.

• Control of an electro valve.

• Utilizing a group of automated sensors.

• Control of a pneumatic cylinder.

• Control systems in Cartesian coordinates.

• Control using a PLC.

• Control using a microprocessor.

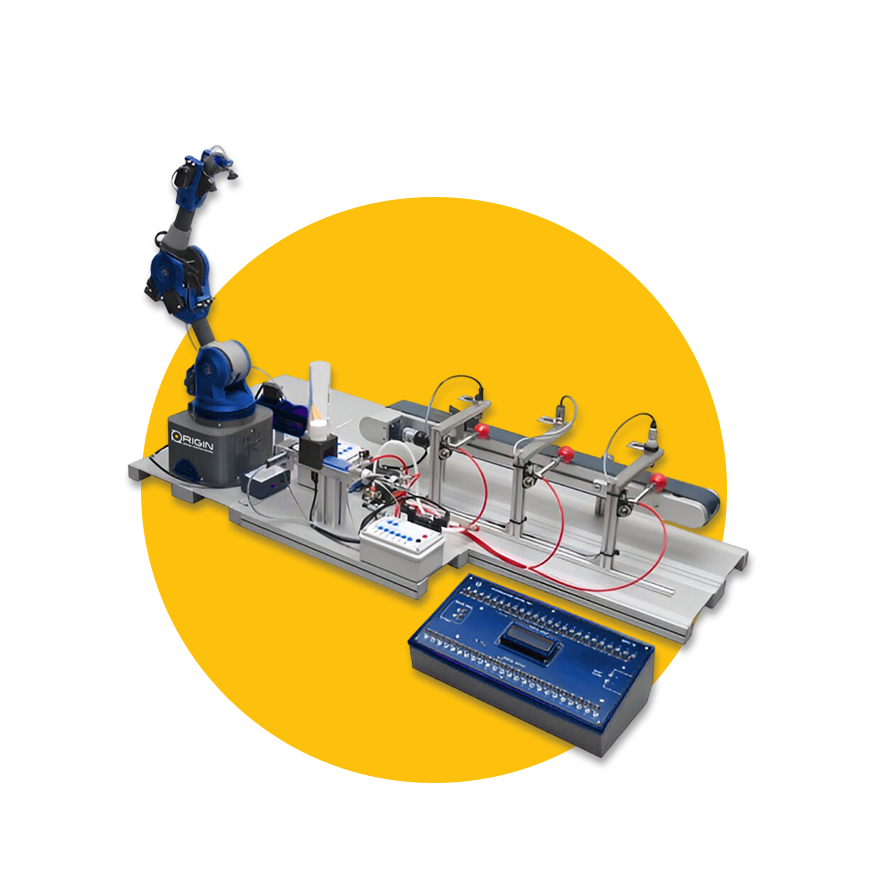

Robot Arm

Code : (MTR-43)

The (MTR-43) Unit has been designed for the manipulation and positioning of objects in various locations.

It is equipped with a series of stepper motors that enable movement along 6 axes in space.

Additionally, it features low voltage servomotors to govern the gripper's rotation.

Control of the device is facilitated by an onboard microprocessor.

To simplify operation, a graphical interface is included for module control.

Furthermore, integration of the robotic arm into multiple automated lines is possible; however, this necessitates adequate digital resources from an external controller.

• Creating a process flowchart.

• Listing the steps in order.

• Defining the inputs and outputs of the system.

• Building the logical diagram.

• Assessing possible issues.

• Coding the program in C/C++.

• Understanding the fundamentals of electronics.

• Understanding the fundamentals of robotics.