Instrumentation Lab Products

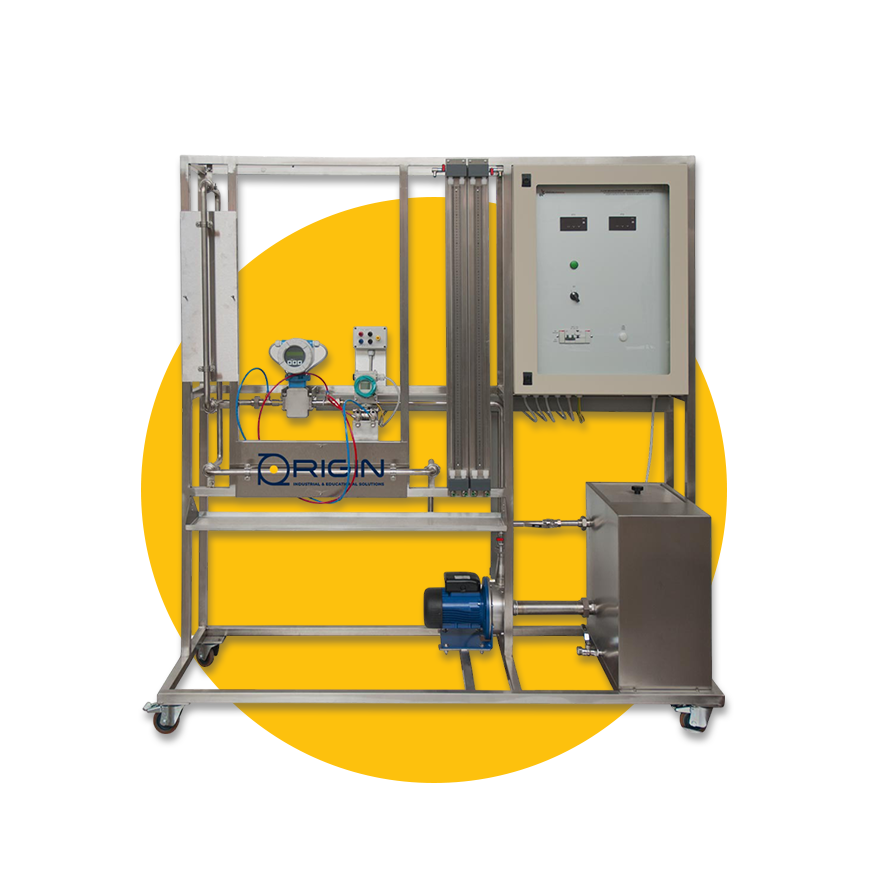

Level and temperature measurement

Code : (MTI-51)

The (MTI-51) unit is utilized for studying fundamental hydrostatic principles, as well as for installing, calibrating, and maintaining process field instruments using a water column.

It consists of a see-through acrylic tank and a feeding tank.

Various designs and makes of instrumentation can be mounted using quick couplings located on the equipment and the tank.

It comes with a differential pressure transmitter.

• Protection provided by E.L.C.B.

• Power supply of 24-Vdc stabilized.

• Unit for air conditioning with compressed air.

• Control board for low voltage electrical systems.

• Components for industrial use.

• Symbols conforming to standards.

• Fully mobile unit.

• Power supply: 230 Vac 50 Hz single-phase - 100 VA.

Pressure measurement unit

Code : (MTI-52)

The (MTI-52 ) unit consists of two pressure chambers, with one designated for high pressure and the other for low pressure.

Each pressure chamber is fitted with a pressure gauge.

The differential pressure transmitter is linked to both chambers.

This module allows for further exploration of the following topics:

• Getting acquainted with a differential pressure transmitter

• Understanding how a differential pressure transmitter operates

Level and flow measurement

Code : (MTI-53)

The top model (MTI-53) unit includes two pressure chambers, with one for high pressure and one for low pressure.

Each of the pressure chambers is fitted with a pressure gauge.

The differential pressure transmitter is linked to both chambers.

This module allows for a more in-depth exploration of the following topics:

• Fundamental principles of operation and various types of flow meters

• Calibrating different types of flow meters

• Properly installing and connecting flow meters

• Understanding how the position affects measurements

• Creating pressure loss plots for flow meters

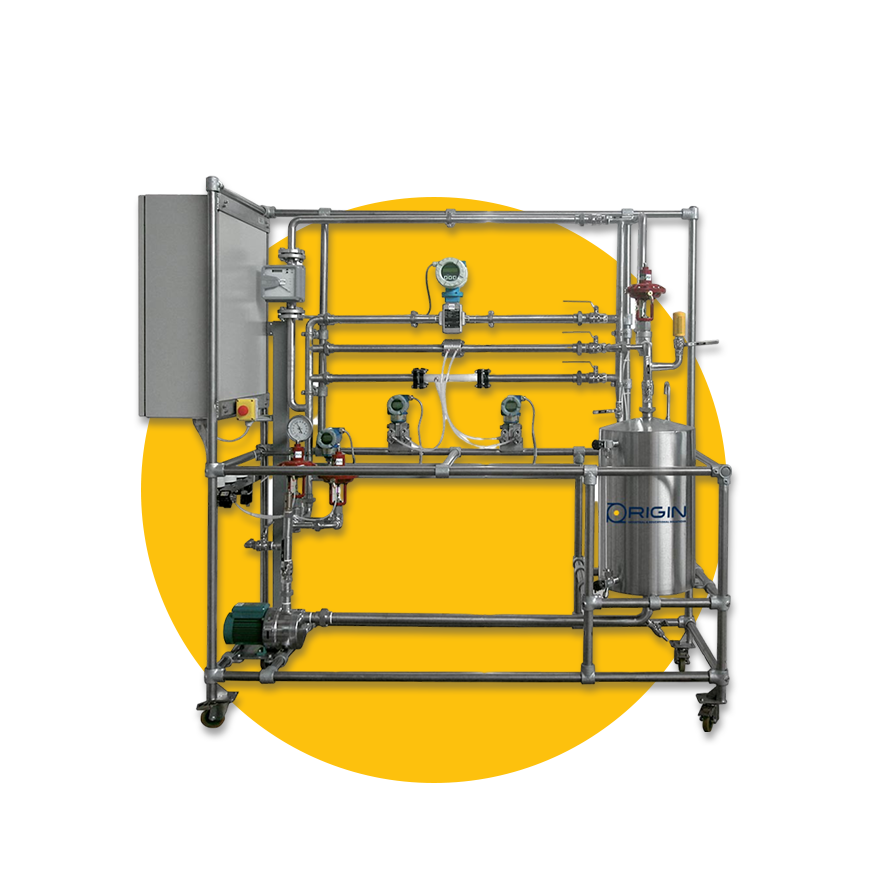

Multi process measurement

Code : (MTI-54)

The (MTI-54) unit comprises a hot water circuit, a cold water circuit, and a heat exchanger that facilitates heat transfer between the two circuits.

Within the cold water circuit, a three-phase pump propels water from the reservoir tank to an upper tank through a pneumatic control valve, serving as actuators for flow, pressure, level, and temperature control loops.

In the hot water circuit, a circulation pump drives water through a heating element and the heat exchanger, with the heating element acting as an actuator for the temperature control loop.

Additionally, the temperature of this circuit can be regulated by controlling the flow circulating through the cold water.

The (MTI-54) unit is equipped with six types of sensors, three actuators, and an industrial controller to execute up to twelve different control loops for level, pressure, temperature, and flow.

Through practical exercises, students will learn the procedure for executing all stages of a PID control loop, taking physical measurements with a sensor, conditioning signals, programming the controller device, configuring the set point value, and adjusting the PID parameters to ensure appropriate process control.

• Exploring the primary components of a control system: sensor, actuator, and controller.

• Creating the piping and instrumentation diagram (PID) for flow, level, pressure, and temperature control system.

• Influence of the parameters of a PID controller.

• Flow control loop variations: Open loop control (manual), on/off control, and Proportional + Integral + Derivative control.

• Adjusting PID settings for a flow control system.

• Impact of disturbances in a flow control system with a PID controller.

• Variations in the level control loop: Open loop control (manual), on/off control, and Proportional + Integral + Derivative control.

• Fine-tuning PID settings for a level control system.

• Effects of disturbances in a level control system with a PID controller.

• Variations in the temperature control loop: Open loop control (manual), on/off control.

• Rewording the TEXT:

• Temperature control loop with Proportional, Integral, and Derivative components.

• Adjusting PID parameters for a temperature control system.

• Impact of external changes on a temperature control system using a PID controller.

• Pressure control loop in manual mode.

• Implementing pressure control with on/off strategy.

• Utilizing Proportional, Integral, and Derivative actions in a pressure control loop.

• Fine-tuning PID settings for a pressure control system.

• Consequences of disturbances in a pressure control system employing a PID controller.

Sensors & actuator training unit

Code : (MTI-55)

The (MTI-55) unit is a comprehensive training kit on sensors and actuators, that include a variety of components like temperature sensors, light sensors, proximity sensors, and actuators such as servo motors, stepper motors, and relays.

Experiments can involve projects like creating a temperature-controlled fan using a temperature sensor and a motor, building an automated light system with a light sensor and relay, and using a proximity sensor to trigger a stepper motor for a simple robotic arm.

The ultimate aim is to enable trainees to grasp each component's function and integration in real-world applications.

• Temperature Control System

• Light-Activated Lamp

• Proximity Sensor-Activated Robotic Arm

• Humidity Monitoring System

• Automated Watering System

• Fan Speed Control Based on Temperature

• Simple Home Automation System

• Smart Doorbell System