Electrical Machine Lab Products

DC machine

Code : (EM-21)

DC machines (EM-21) are still used for educational purposes, serving as the foundation for understanding electrical machines.

They provide a clear demonstration of the different options for controlling machines using open- and closed-loop systems.

Operation of the motor involves:

- Connecting the motor

- Comparing shunt-wound, series-wound, and compound-wound machines

- Reviewing typical machine data

- Implementing open-loop speed control with starter and field regulator

- Reversing the rotation direction

- Analyzing load characteristics at constant input voltage

- Conducting measurement evaluations

Generator operation includes:

- Connecting the generator

- Examining armature voltage in relation to the exciter current

- Understanding the function and application of the field regulator

- Controlling voltage, self-excitation, and separate excitation

- Analyzing armature current and voltage at constant speed and exciter current

- Creating a load diagram of the generator

Single phase induction motor

Code : (EM-22)

The Single-phase motors with operating and starting capacitors in the (EM-22) unit are asynchronous (induction) machines.

Alongside the primary winding, they feature an auxiliary winding that is connected in series to the capacitor.

These motors lack components that are susceptible to wear and tear, such as collectors or slip-rings, and they operate at an almost synchronous rotation speed.

Their power range extends up to approximately 2 kW.

Capacitor motors are utilized for powering household appliances, refrigerators, and even small drives in production machinery.

• Connecting, wiring, and commissioning

• Changing the direction of rotation

• Operating with or without a starting capacitor

• Measuring the speed-torque characteristic

• Starting up with or without a starting capacitor

• Examining current relays

Three phase induction motor

Code : (EM-23)

Asynchronous machines are available with power ratings reaching into the megawatt range.

The simple design of asynchronous squirrel-cage (EM-23) unit machines makes them especially common.

• Connecting the motor

• Changing the direction of rotation

• Switching manually

• Specific values and characteristics of the machine

• Assessing measurements

• Using star-delta connection

• Utilizing Steinmetz circuit

• Compensating reactive power with capacitors of different capacitance values

AC machine

Code : (EM-24)

An AC machine training unit is a sophisticated educational platform designed to provide hands-on experience and theoretical knowledge about alternating current (AC) machines, such as induction motors, synchronous motors, and generators.

These units are essential for students, engineers, and technicians in electrical engineering and related fields.

• Performance Characteristics of Induction Motors

• Starting Methods of Induction Motors

• Speed Control of Induction Motors Using VFD

• Torque-Speed Characteristics of Synchronous Motors

• Power Factor Measurement

• Alternator Performance Testing

• Harmonic Analysis in AC Circuits

• Winding Resistance Measurement

• Load Testing of AC Machines

• Overload and Short-Circuit Testing

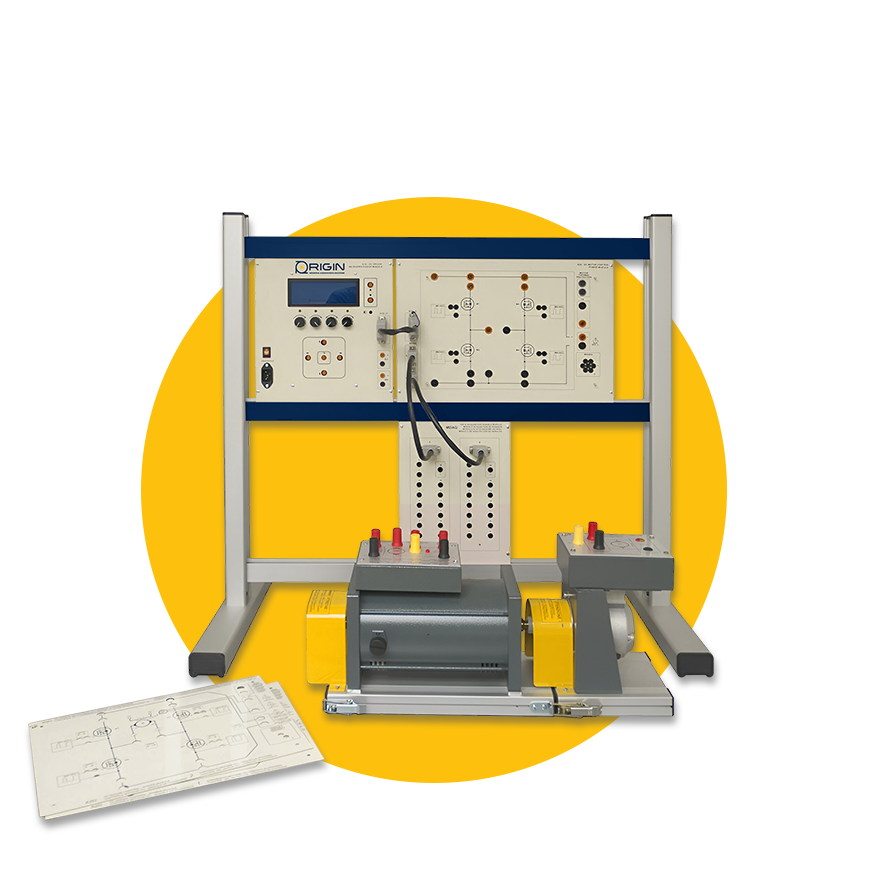

Modular educational system for drives DC motors

Code : (EM-25)

The field of Power Electronics deals with static power conversion and its various applications.

The (EM-25) unit has been specifically created using industrial components and in accordance with educational standards.

It serves as the ideal tool for both theoretical and practical study of DC motor drive.

• The features of DC motors related to mechanics and electricity.

• DC motors are driven by 2Q MOSFET technology, which includes control and power circuits.

• DC motors can also be driven by 4Q MOSFET technology, which consists of control and power circuits.

Modular educational system for drives AC motors

Code : (EM-26)

Modern frequency converters transform any given three phase robust nature and broad popularity of the three-phase standard motor have played a major role in the success enjoyed by electronic drive technology with frequency converters.

The higher demands placed on drives due to rapid advances in process automation means that more and more motors are controlled by frequency converters.

Thanks to needs-based open-loop speed control, today it is possible to save substantial amounts of energy in pumps and air-conditioning systems.

• Sinamics G120 is a single-phase frequency converter with a power of 0.75 kW and PROFINET capability.

• A 0.2 kW brake resistor is designed for use with frequency converters.

• The three-phase asynchronous motor operates at 0.3 kW with a speed of 1400 rpm and can be used with both 230V and 400V power supplies.

• The Interactive Lab Assistant is an industrial single-phase 0.3 kW frequency converter.

• Additionally, a dynamic servo machine test stand is needed for 0.3 kW machines and should include Active Servo software.

• A rubber coupling sleeve suitable for 300W machines is required.

• For 300W machines, a coupling guard with LED lighting is necessary.

• The electrical machines will need a three-phase supply.

• A power multimeter is also needed for this setup.