Process Control LAB Products

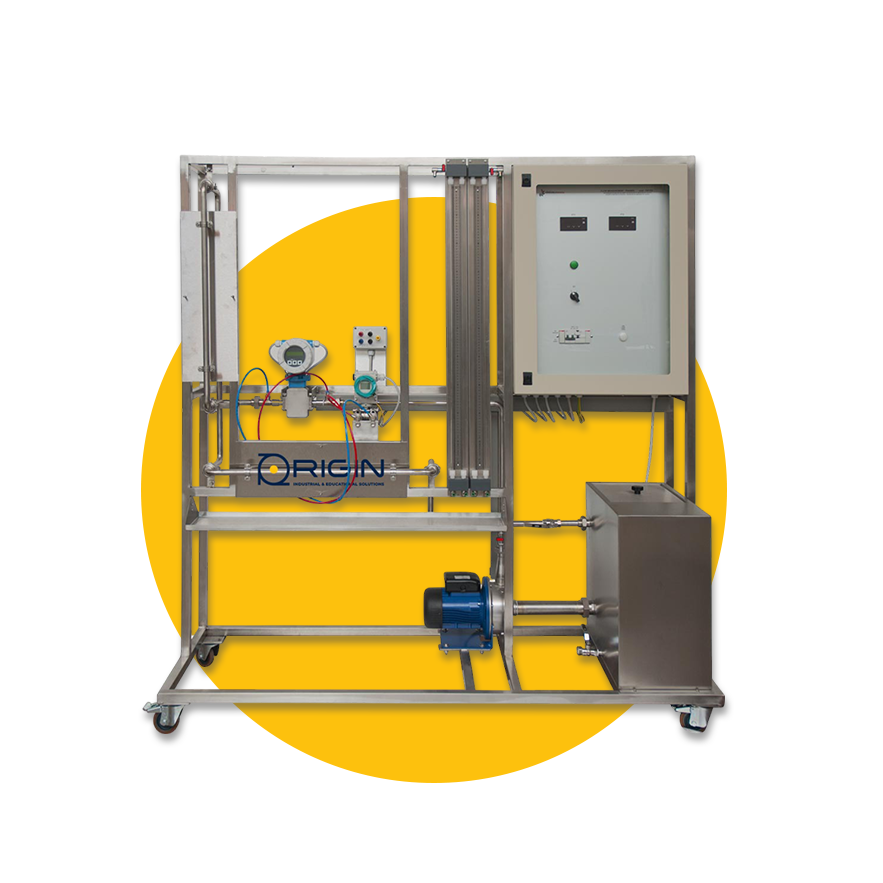

Flowrate control

Code : (MTP-21)

Flow process control trainer is designed to demonstrate the concept of one of the important process in industry which is PID.

The trainer aims to investigate the principle of PID in flow process.

• Investigation of open and closed loop systems.

• Demonstration of different types of controllers (P, PI,PID)

• Investigation of the response of different types of controllers (P, PI, PID).

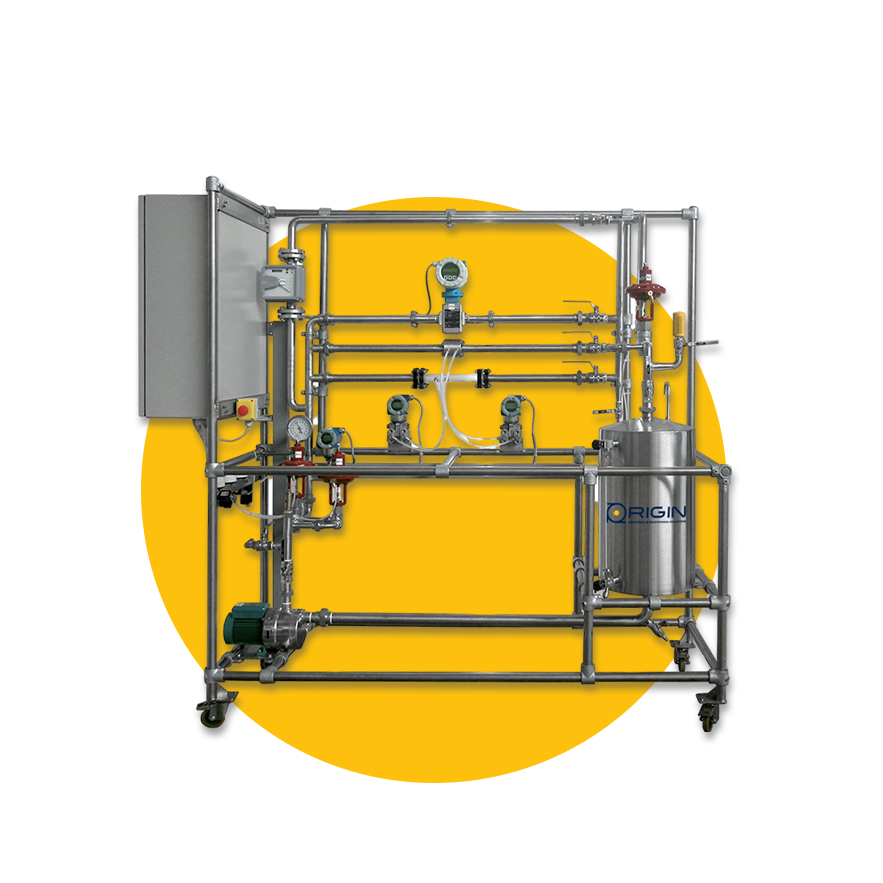

Level and flow rate control

Code : (MTP-22)

Level and flow process control trainer is designed to demonstrate the concept of one of the important process in industry which is PID.

The trainer aims to investigate the principle of PID in level and flow process

• Investigation of open and closed loop systems.

• Demonstration of different types of controllers (P, PI,PID)

• Investigation of the response of different types of controllers (P, PI, PID).

DC motor position PID Controller

Code : (MTP-23)

Position process control trainer is designed to demonstrate the concept of one of the important process in industry which is PID.

The trainer aims to investigate the principle of PID in position process.

• Investigation of open and closed loop systems.

• Demonstration of different types of controllers (P, PI,PID)

• Investigation of the response of different types of controllers (P, PI, PID).

DC motor speed control

Code : (MTP-24)

Speed process control trainer is designed to demonstrate the concept of one of the important process in industry which is PID.

The trainer aims to investigate the principle of PID in speed process.

• Investigation of open and closed loop systems.

• Demonstration of different types of controllers (P, PI,PID)

• Investigation of the response of different types of controllers (P, PI, PID).

PLC Based process control

Code : (MTP-25)

PLC - based process control trainer is designed to provide a practical training on controlling an industrial process using two methods either through using PLC unit.

The trainer is capable of presenting process control real malfunctions, with realistic dynamic behavior and instabilities.

The trainer demonstrates the methods of controlling the four main parameters found in any industrial process namely, pressure, temperature, flow and level.

• Measurement of electrical and process-control variables like liquid level, flow

rate, pressure and temperature.

• Design, assembly and commissioning of control loops.

• Setting parameters and optimizing P-action, PI-action and PID-action controllers.

• Using control devices to adjust system conditions and parameters, as well as

managing disturbances.

• Gaining understanding of the distinctions between open loop control system

and closed loop control system.

Pressure PID control

Code : (MTP-26)

This type of training kit is typically used to teach students and professionals about the principles and practical applications of pressure process control in various industrial settings.

Such kits usually include components like pressure sensors, controllers, valves, and other related equipment to simulate real-world process control scenarios.

• Investigation of open and closed loop systems.

• Demonstration of different types of controllers (P, PI,PID)

• Investigation of the response of different types of controllers (P, PI, PID).

Temperature PID control

Code : (MTP-27)

Temperature process control trainer is designed to demonstrate the concept of one of the important process in industry which is PID.

The trainer aims to investigate the principle of PID in temperature

• Investigation of open and closed loop systems.

• Demonstration of different types of controllers (P, PI,PID)

• Investigation of the response of different types of controllers (P, PI, PID).